Unveiling the Challenges of Eco-Friendly Resins

The Hidden Downsides of Thixotropic, Pre-Accelerated Resins

Explore the potential pitfalls of using thixotropic, pre-accelerated resins with recycled PET content in construction and roofing projects.

Key Characteristics of Thixotropic Resins

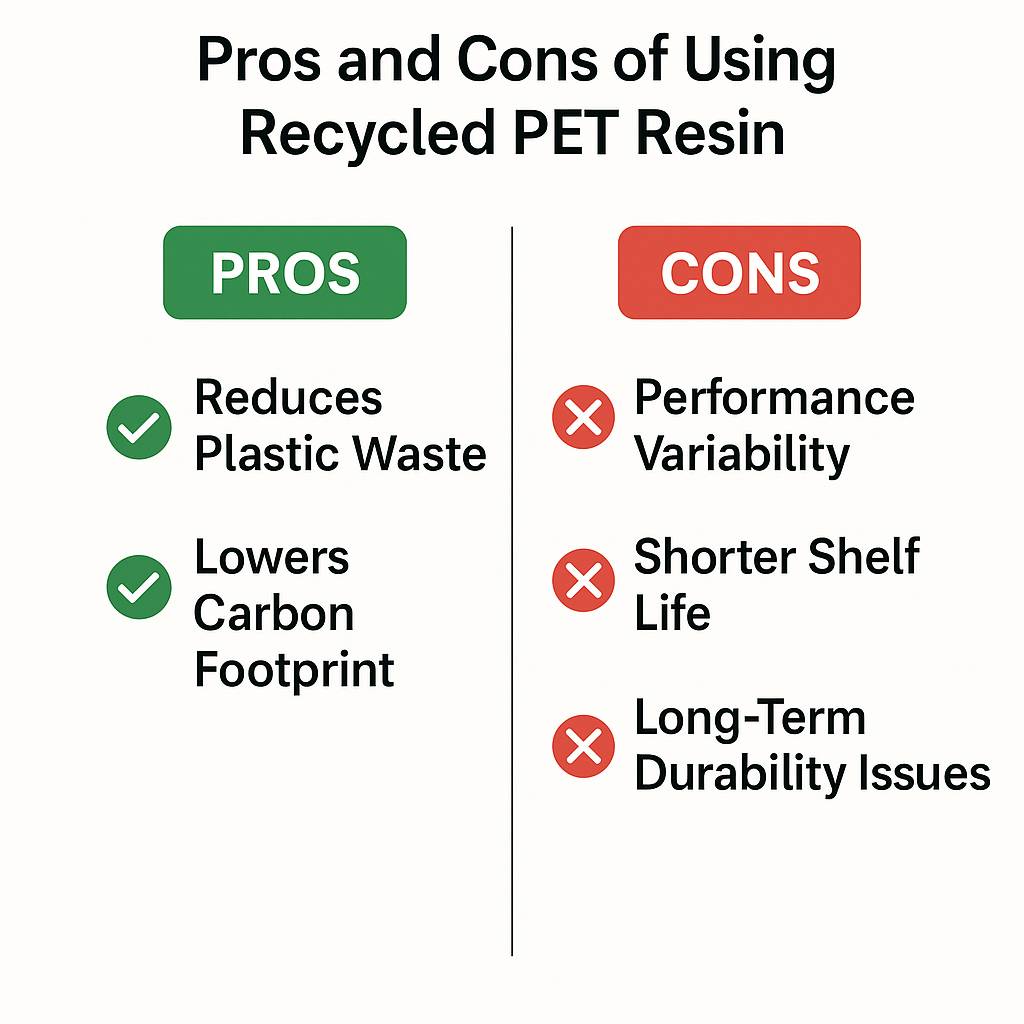

In the drive toward greener construction and roofing solutions, thixotropic, pre-accelerated resins incorporating recycled PET (polyethylene terephthalate) have gained popularity. These innovative materials help reduce carbon footprints and promote the reuse of waste plastics — important steps for sustainability across industries.

However, while environmentally beneficial, these resins are not without potential downsides. Installers, specifiers, and property owners should be fully aware of the material’s limitations before choosing it for critical applications.

Performance Variability Due to Recycled Inputs

Using recycled PET introduces certain inconsistencies:

Quality Fluctuations: Variability in recycled PET feedstock can affect mechanical properties like strength, flexibility, and cure time.

Contamination Risk: Impurities within the recycled material may impact chemical stability, potentially leading to bonding failures or reduced lifespan.

Although manufacturers work to control these factors, achieving the consistency seen with virgin resins remains a challenge.

Reduced Transparency and Surface Finish Quality

Recycled PET-based resins can display:

Discolouration: Minor haze, yellowing, or cloudiness may occur, especially over time.

Surface Imperfections: Achieving a completely smooth, clear finish can be harder compared to traditional virgin-based resins.

While cosmetic flaws may be irrelevant for purely functional installations, they can be problematic where visual appearance is important.

Understanding Resin Sensitivities

Navigating the Challenges of Thixotropic Resins

Thixotropic, pre-accelerated resins, while eco-friendly, require careful handling due to their sensitivity to storage conditions. These resins can prematurely thicken or partially cure if exposed to extreme temperatures or humidity. Proper mixing is crucial to ensure uniform application and optimal performance.

Incorporating recycled PET into resins offers environmental benefits but also introduces variability in performance. Installers must be aware of potential quality fluctuations and contamination risks that can affect the resin’s mechanical properties and longevity. Understanding these factors is essential for successful application in construction projects.

Key Insights into Eco-Friendly Resins

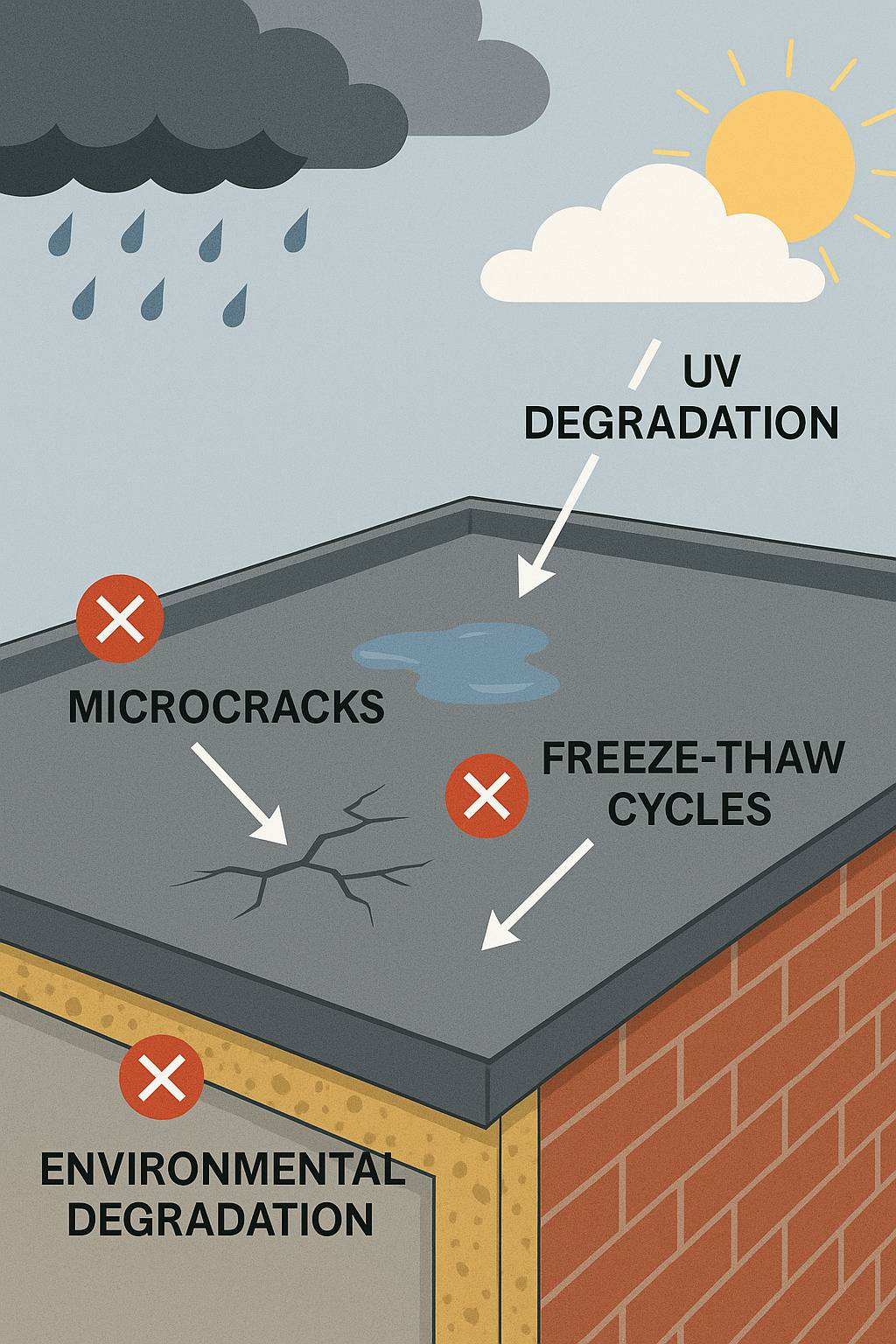

Potential for Weaker Long-Term Durability

While performance at installation can be excellent, questions remain about durability under long-term environmental stress:

Microcracking Susceptibility: Differences in thermal expansion between the recycled PET and the resin matrix can cause microscopic cracks over years of freeze-thaw cycling.

Environmental Degradation: Prolonged exposure to UV light, pollutants, and moisture may accelerate the breakdown of some recycled-content formulations if not perfectly engineered.

This is particularly important in regions with variable or harsh weather conditions.

Understanding Thixotropic Resins

Get insights into common concerns and queries about using thixotropic, pre-accelerated resins in your projects.

What are the main limitations of using these resins?

How do these resins impact the environment?

Are these resins suitable for all construction projects?

What should installers be aware of when using these resins?

Can these resins be used in roofing applications?

What are the cost implications of using these resins?

Potential Cost vs. Performance Trade-Off

Choosing sustainable materials often involves balancing priorities:

Material Costs: Despite using recycled inputs, the additional processing and need for consistent quality control can make these resins as costly — or sometimes more costly — than traditional options.

Life Cycle Costs: If repairs, recoating, or maintenance are required earlier, the overall cost of ownership may be higher, negating some of the intended environmental benefits.

It is vital for decision-makers to consider not only initial eco-credentials but also full-life performance and maintenance requirements.

Final Thoughts

Choosing sustainable materials like thixotropic, pre-accelerated resins with recycled PET is a step towards eco-friendly construction. However, understanding their limitations and ensuring proper application is crucial for long-term success.

While these materials offer significant environmental benefits, they also present challenges such as performance variability and potential durability issues. It’s essential to weigh these factors carefully when making decisions.

Ultimately, the key to successful implementation lies in thorough training, regular inspections, and a commitment to balancing sustainability with performance. By doing so, we can ensure that these innovative materials deliver the intended benefits without compromising quality.