Introduction

Welcome to the definitive guide for mastering GRP roofing! In this comprehensive article, we’ll delve into the intricacies of Glass Reinforced Plastic (GRP) roofing, offering invaluable insights for both professionals and DIY enthusiasts. From understanding the fundamentals to exploring advanced techniques, this guide is your go-to resource for achieving excellence in GRP roofing projects. Let’s embark on a journey to unlock the secrets and master the art of GRP roofing!

Unveiling the World of how to Master GRP Roofing

Understanding GRP Roofing

GRP roofing, or Glass Reinforced Plastic roofing, stands as a versatile and durable solution increasingly favored in various construction projects. Composed of a matrix of polyester resin reinforced with glass fibers, GRP roofing exhibits exceptional durability, weather resistance, and an impressive lifespan. Its composition makes it an ideal choice for withstanding the challenges posed by the elements.

Composition and Structure

GRP roofing is a composite structure that combines the strength of polyester resin with the reinforcement of glass fibers. This synthesis creates a robust matrix that excels in durability and resistance to various weather conditions.

Durability and Weather Resistance

GRP roofing’s inherent strength allows it to withstand environmental challenges, including heavy rainfall, extreme temperatures, and exposure to UV rays. Its remarkable durability ensures reliable protection in diverse weather conditions.

Impressive Lifespan

Boasting an impressive lifespan, GRP roofing is a sustainable and cost-effective choice. The material’s resilience contributes to reduced maintenance requirements, making it a durable, long-term roofing solution.

Ideal for Elements

GRP roofing’s composition and properties make it an ideal choice for structures facing challenges posed by the elements. It can resist corrosion from rainfall, withstand harsh sunlight, and maintain structural integrity in various environmental conditions.

Navigating GRP Roofing Kits

- GRP roofing kits play a pivotal role in simplifying the roofing process for both professionals and DIY enthusiasts. Crafted with convenience, cost-effectiveness, and all-in-one solutions in mind, these kits provide pre-packaged materials, streamlining the process and reducing the likelihood of errors.

Streamlined Process

- GRP roofing kits eliminate the need for extensive material sourcing, making the roofing process accessible to a wider audience. Whether you’re a professional or a DIY enthusiast, these kits save time by conveniently packaging all necessary materials in one bundle.

Convenience and Cost-Effectiveness

- The convenience offered by GRP roofing kits extends to both time and cost. Bundling materials in a kit not only saves time on individual component searches but also contributes to cost-effectiveness through bundled pricing.

All-in-One Solutions

- Comprehensive and all-encompassing, GRP roofing kits include all essential components—basecoats, topcoats, resin, catalyst, reinforcement mat, and application tools. This holistic approach simplifies decision-making and ensures a seamless installation process.

BasecoatThe basecoat serves as the foundational waterproofing layer, bonding to the substrate and creating a stable surface for subsequent layers.

TopcoatAs the protective outer layer, the topcoat enhances the roofing system’s resilience, providing weather resistance, UV protection, and a finishing touch.

ResinActing as the bonding agent, resin ensures adhesion of the reinforcement mat and contributes to the overall strength of the roofing structure.

Catalyst

The catalyst initiates the resin curing process, with proper proportions essential for achieving desired curing times and system effectiveness.

Reinforcement Mat

Reinforcing the roofing system, the mat adds strength and durability, working in tandem with the resin to create a robust composite structure.

Application Tools

Rollers and brushes, essential application tools, play a crucial role in achieving a smooth and even application of GRP roofing materials. Proper tool use ensures optimal results in the installation process.

Master GRP Roofing by Choosing the Right GRP Roofing Kit

- Selecting the right GRP roofing kit is a critical step in ensuring project success. Considerations include project requirements, roof size, budget constraints, and the quality of materials. Compatibility with specific roofing substrates also plays a crucial role in achieving optimal results.

Project Requirements

- Understanding the unique requirements of your roofing project is essential. Consider factors such as the type of roof, size, and specific challenges the project may pose.

Roof Size

- The size of your roof directly influences the quantity of materials needed. Ensure that the selected kit provides adequate coverage for your specific roof dimensions.

Budget Constraints

- Establish a realistic budget and choose a GRP roofing kit that aligns with your financial constraints. Consider overall cost-effectiveness, factoring in material quality and bundled pricing.

Quality of Materials

- The quality of materials within the kit is paramount to the success and longevity of your roofing system. Opt for kits that include high-quality basecoats, topcoats, resins, and reinforcement mats.

Compatibility

- Consider the compatibility of the GRP roofing kit with specific roofing substrates. Ensure that the chosen kit is suitable for the type of roofing surface you are working with, whether it’s flat, pitched, or another configuration.

Warranty

- Check for warranties offered with GRP roofing kits. A reliable warranty provides assurance of material quality and the manufacturer’s confidence in their product.

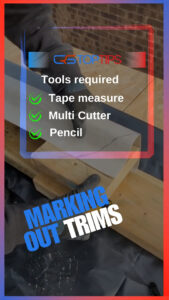

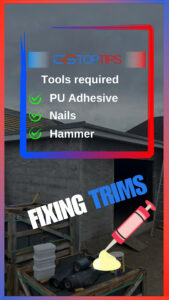

Perfecting with GRP Trims

- GRP trims play a pivotal role in enhancing both the functionality and aesthetics of a roofing system. These specially designed components contribute to edge protection, create clean roof finishes, and prevent water ingress. Understanding the significance of GRP trims is crucial for ensuring a watertight and visually appealing roof that can withstand external elements.

Edge Protection

GRP trims provide essential edge protection to the roofing system, acting as a barrier against potential damage from external elements, foot traffic, or weather conditions.

Aesthetics

Beyond functionality, GRP trims significantly contribute to the overall aesthetics of a roof, creating clean and polished finishes that enhance the visual appeal of the roofing structure.

Water Ingress Prevention

One of the primary functions of GRP trims is to prevent water ingress by sealing edges and vulnerable areas, ensuring that water cannot penetrate the roofing system and protecting the underlying structure.

Types and Functions of GRP Trims

Understanding Various GRP Trim Types

GRP trims come in various types, each serving specific functions in different roofing scenarios. The choice of trim type depends on architectural design, roof configuration, and the level of protection required in specific areas.

Corner Trims

Designed for angular or corner sections of the roof, corner trims provide reinforcement and protection to these vulnerable areas, ensuring durability and a polished appearance.

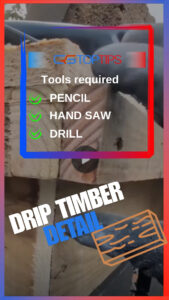

Drip Trims

Installed at the eaves or edges of the roof, drip trims manage water runoff, preventing water from pooling or causing damage by channeling it away.

Verge Trims

Utilized at the gable ends or edges of a roof, verge trims offer protection and a finished look to these exposed areas, contributing to the overall aesthetics of the roofing system.

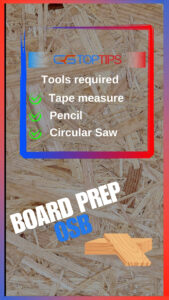

Identifying Essential Tools for bring the of Master GRP Roofing

- Identifying and using the right tools is crucial for the success of GRP roofing installation. Proper tools ensure a smooth and efficient application process, contributing to optimal results and safety.

Rollers

- Rollers are instrumental in achieving a smooth and even application of GRP roofing materials, ensuring proper adhesion and creating a seamless finish.

Brushes

- Brushes play a crucial role in applying materials to intricate or detailed areas of the roof, ensuring that every part is adequately coated for maximum effectiveness.

Mixing Containers

- Proper mixing is essential for resin activation. Having the right mixing containers ensures accurate proportions, contributing to the success of the curing process.

Cutting Tools

- Precision is key during the installation process. Cutting tools help tailor materials to fit specific areas of the roof, ensuring a precise and neat application.

Safety Equipment

- Ensuring the safety of the roofing team is paramount. Safety equipment, including gloves, goggles, and protective clothing, should be worn to prevent accidents and exposure to potentially harmful substances.

Examining Characteristics and Benefits Master GRP Roofing

Fibreglass roofing materials complement GRP roofing systems, enhancing their characteristics and benefits. Understanding the properties of fibreglass and its role in roofing applications is essential for a comprehensive grasp of GRP roofing.

Lightweight Nature

- Fibreglass roofing materials are known for their lightweight nature, adding minimal load to the structure while maintaining strength and durability.

Flexibility

- The flexibility of fibreglass allows it to adapt to various roof shapes and configurations, making it suitable for a wide range of architectural designs.

Resistance to Corrosion

- Fibreglass exhibits excellent resistance to corrosion, ensuring that it remains structurally sound even in corrosive environments or exposure to harsh weather conditions.

Chemical Resistance

- The chemical resistance of fibreglass makes it an ideal choice for roofing applications, as it can withstand exposure to various chemicals without compromising its integrity.

Reinforcing GRP Systems

- Fibreglass reinforces GRP roofing systems, adding an extra layer of strength and durability. This integration enhances the overall performance and longevity of the roofing structure.

DIY Adventures with GRP Roofing

For DIY enthusiasts, GRP roofing opens up a realm of possibilities. From flat roof installations to repairs and extensions, embarking on DIY adventures with GRP roofing materials is both rewarding and achievable.

Flat Roof Installations

GRP roofing is well-suited for flat roof installations, providing a seamless and durable solution. DIYers can confidently take on this project with the right materials and guidance.

Repairs

GRP roofing allows for effective repairs, addressing issues such as leaks or damage. DIY enthusiasts can save costs by undertaking minor repairs using GRP materials.

Extensions

Adding extensions to existing roofs can be a fulfilling DIY project with GRP roofing. The versatility of the material allows for seamless integration, creating a cohesive and aesthetically pleasing result.

Mastery of Installation: A Step-by-Step Guide

Step-by-Step Guide for Installing a GRP Roof

Mastering the installation process is crucial for achieving optimal results with GRP roofing. This step-by-step guide provides a comprehensive overview of the installation process, ensuring success from preparation to finishing touches.

Preparation

Thoroughly prepare the roof surface by cleaning and ensuring it is free from debris. Proper surface preparation is key to the adhesion and effectiveness of the GRP roofing system.

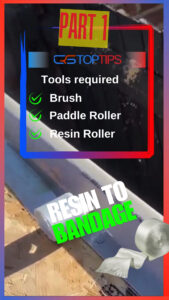

Basecoat Application

Apply the basecoat evenly across the prepared surface, ensuring complete coverage. The basecoat serves as the initial waterproofing layer and provides a stable foundation for subsequent layers.

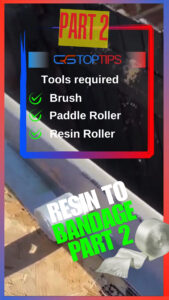

Matting Reinforcement

Lay the reinforcement mat onto the wet basecoat, ensuring it is fully saturated with resin. The reinforcement mat adds strength and durability to the roofing system.

Topcoat Application

Apply the topcoat over the reinforcement mat, ensuring an even and smooth finish. The topcoat provides additional protection, weather resistance, and a final aesthetic touch.

Finishing Touches

Inspect the finished roof for any imperfections or irregularities. Make necessary adjustments and ensure that all components are seamlessly integrated for a polished final result.

Avoiding Mistakes in DIY GRP Roofing

Master GRP Roofing & Steering Clear of Common DIY Mistakes While undertaking DIY GRP roofing projects is rewarding, it’s essential to be aware of common mistakes and how to avoid them. By addressing potential pitfalls, DIYers can ensure the success and longevity of their GRP roofing installations. Improper Resin Mixing RatiosAchieving the correct resin mixing ratios is crucial for the curing process. Measure and mix resin and catalyst accurately to avoid issues such as incomplete curing or compromised structural integrity.Inadequate Surface Preparation Properly preparing the roof surface ensures optimal adhesion of GRP roofing materials. Neglecting this step can lead to poor adhesion, reducing the effectiveness of the roofing system. Inconsistent Application Techniques

Maintaining consistency in application techniques, especially when applying basecoats, reinforcement mats, and topcoats, is essential for achieving a uniform and effective roofing system.

Conclusion: Master GRP Roofing

In conclusion, mastering GRP roofing involves a comprehensive understanding of its composition, the role of key components, the selection of appropriate kits, the significance of trims, the use of essential tools, and the integration of fibreglass materials. Whether you’re a professional roofer or a DIY enthusiast, this guide equips you with the knowledge and insights needed to excel in GRP roofing projects.

As you embark on your GRP roofing journey, consider the benefits of this versatile roofing solution, explore the convenience of kits, and embrace the possibilities of DIY adventures. By following the step-by-step installation guide and steering clear of common mistakes, you can achieve a watertight, durable, and aesthetically pleasing GRP roof.

Full Video Link How to fibreglass a roof

What is GRP in roofing?

GRP stands for Glass Reinforced Plastic, which is a type of roofing material commonly used in the construction industry. A GRP roof can last up to 30 years with proper installation and maintenance.

Which is better rubber or GRP roofing?

When it comes to choosing between rubber and GRP roofing, it depends on various factors such as budget, aesthetic preferences, and specific requirements of the project. Both materials have their advantages and disadvantages. GRP roofing is known for its durability, water-resistance, and versatility in design, while rubber roofing is often chosen for its flexibility, ease of installation, and cost-effectiveness.

How long will a GRP roof last?

GRP roofs are generally considered to be good roofing options due to their long lifespan, excellent waterproofing properties, and resistance to UV rays, corrosion, and temperature fluctuations. However, it is important to ensure that the installation is done by professionals and proper maintenance is carried out to maximize the lifespan and performance of the GRP roof.